ERP Software is specially designed for Engineering Companies including Process and Discreet Industry. It supports various manufacturing environments like make-to-order (MTO) and make-to-stock (MTS) using either a highly repetitive or process order-based system, engineer-to-order (ETO), one-off or job shop environment. It understands this and offers a comprehensive solution for your entire manufacturing business; from raw materials to final product to distribution and finance. In addition to MTO/MTS manufacturers, It has comprehensive and deep functionality ECN – Engineering Change Note and Design Department which covers DCR – Drawing Change Request, DCN – Drawing Change Note, Design BOM – Customize Bill of Material. It discrete manufacturing ERP systems are the result of over 10 years of working.

MAKE-TO-ORDER MANUFACTURING:

A business production strategy that typically allows consumers to purchase products that are customized to their specifications. The make to order (MTO) strategy only manufactures the end product once the customer places the order. This creates additional wait time for the consumer to receive the product, but allows for more flexible customization compared to purchasing from retailers’ shelves. This covers manufacturers who build and stock all of the product’s components anticipating a customer’s order. When ordered, the final product is assembled and packaged. This category includes manufacturers that produce specific items such as medium and heavy size machinery, industrial ro plants, etc. The Make-To-Order process stocks the components used in the final product, at the semifinish or at the raw material level. When ordered, they are configured into the deliverable product.

ENGINEER-TO-ORDER MANUFACTURING:

Engineer to Order is a manufacturing process defined by demand driven practices in which the component is designed, engineered, and built to specifications only after the order has been received. These types of manufacturers produce goods that require specialized engineering design or considerable customization. Often, a different set of part numbers, bills of materials, and process routes are created for each order. These types of orders can run for many months or even years. This approach is only appropriate for specific and rare items, such as large projects.

MAKE-TO-STOCK MANUFACTURING:

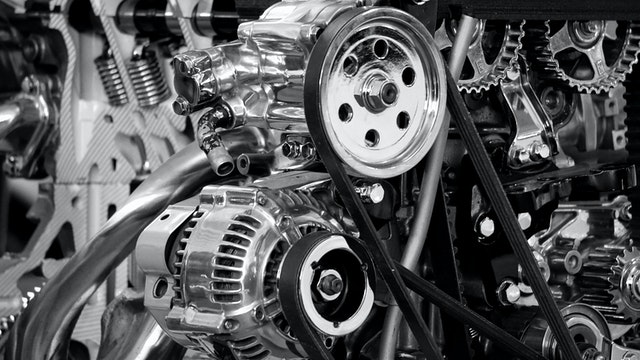

A traditional production strategy used by businesses to match production with consumer demand forecasts. The make-to-stock (MTS) method forecasts demand to determine how much stock should be produced. If demand for the product can be accurately forecasted, the MTS strategy can be an efficient choice. This category includes manufacturers that produce specific items such as filters, domestic ro system, automobile parts, etc. Usually, each item is made through the assembly of component parts. Make-to-stock items are typically completed before an actual customer order has been received.

Modules & Features of Eng. ERP

- Marketing & Sales Management

- Design Management

- Serial Number wise Inventory and Production Management

- Billing Breakup Management

- Production Management with ECN, Design BOM, DCR, DCN, MRP1 & MRP2 Concepts

- Inventory Management with Attributes like Serial No., Heat.

- Procurement Management

- Packaging and Transportation Management

- Costing Management

- Finance Management

- Human Resource Management

- Quality Control Management

- Machine & Plant Maintenance

- Consignment Costing

- Pre-Process, In-Process, Post-Process and Inventory QC

- Security Gate Management

- ISO Required Report Generation

- After Sales Service Management